Expert Tips for Optimizing Your Ford Fiesta Engine Efficiency

Expert Tips for Optimizing Your Ford Fiesta Engine Efficiency

Blog Article

Unlocking the Power of Engines: A Comprehensive Guide to Efficiency and Performance

Recognizing the elaborate technicians of engines is crucial for both performance fanatics and daily drivers. The answers may redefine our strategy to engine efficiency and performance in methods that are both enlightening and vital.

Recognizing Engine Fundamentals

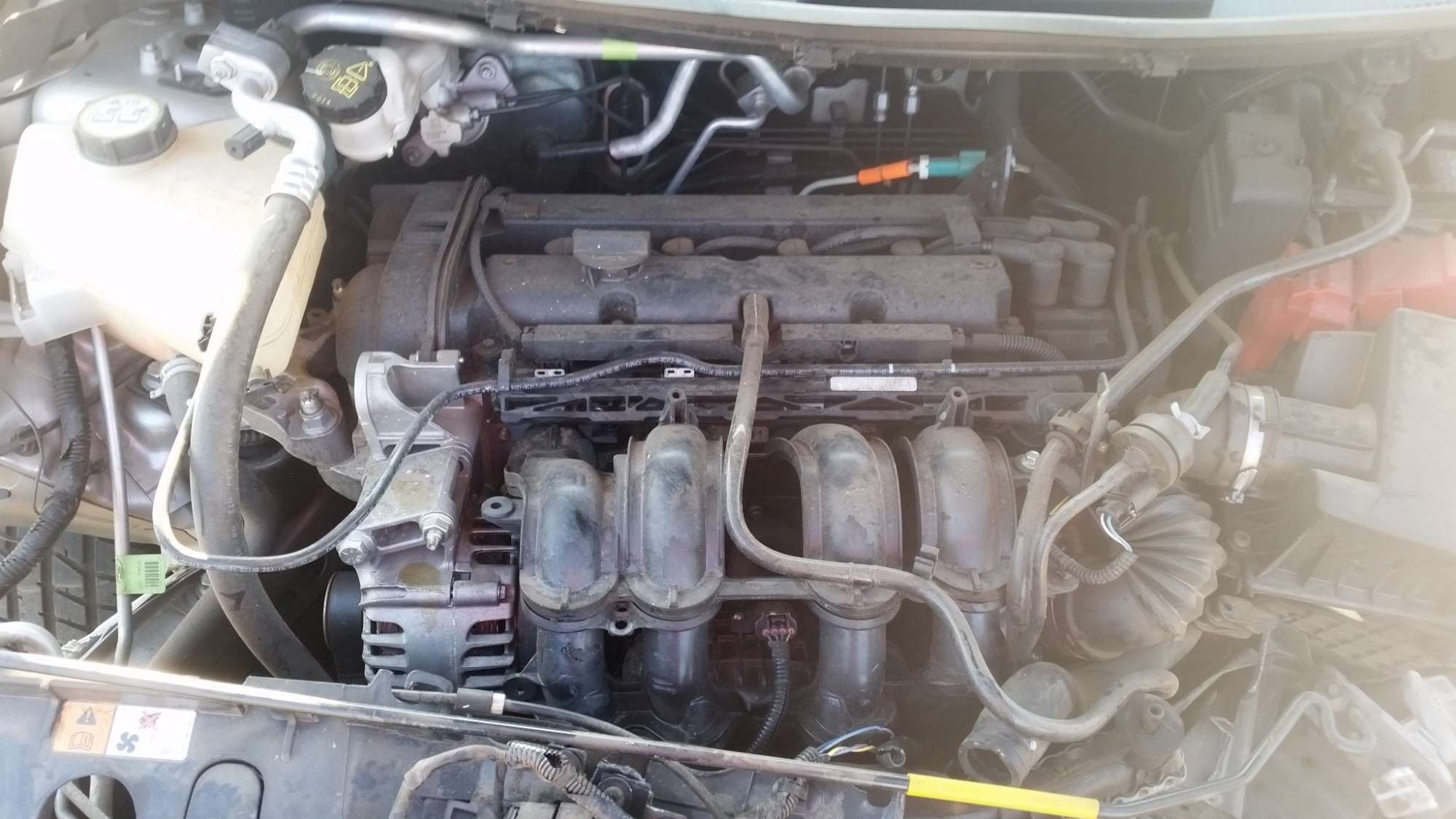

What constitutes the fundamental auto mechanics of an engine? At its core, an engine is an equipment made to transform fuel right into mechanical energy with a collection of regulated surges or burning processes. The primary parts consist of the cyndrical tube, piston, crankshaft, camshaft, and shutoffs. The cyndrical tube functions as the chamber where combustion takes place, while the piston moves within the cylinder to convert the power from combustion into straight motion (ford fiesta engine).

The crankshaft after that changes this direct movement into rotational power, which ultimately powers the car. The camshaft manages the opening and closing of the valves, managing the intake of air and gas and the expulsion of exhaust gases. Furthermore, the engine relies upon a carefully adjusted fuel-air combination, ignition system, and cooling system to make sure optimal performance and effectiveness.

Understanding engine essentials additionally involves identifying the relevance of engine cycles, such as the four-stroke cycle, that includes consumption, exhaust, power, and compression strokes. Each stage is crucial in guaranteeing the engine functions efficiently and properly. Mastery of these essential technicians lays the foundation for exploring a lot more intricate engine dynamics and efficiency metrics, essential for enhancing both power result and efficiency.

Secret Efficiency Metrics

Trick performance metrics are vital for assessing an engine's performance and power output, offering useful understandings for both manufacturers and consumers. These metrics function as standards for engine performance, permitting notified choices in buying, layout, and manufacturing.

One of the primary metrics is horsepower, which quantifies the engine's ability to perform job over time. Torque, measured in pound-feet, is one more vital metric that suggests the engine's rotational force, directly impacting velocity and lugging capacity. Gas effectiveness, normally measured in miles per gallon (MPG) or litres per 100 kilometers (L/100km), assesses how efficiently the engine transforms fuel right into motion, affecting operational expenses and environmental considerations.

Additionally, thermal performance measures how well an engine converts fuel energy right into valuable work, disclosing understandings right into energy losses largely with heat. Emission degrees, including CO2 and NOx, are additionally vital, reflecting the engine's ecological effect and conformity with governing requirements.

Tuning Techniques for Efficiency

Tuning strategies play a substantial function in improving engine efficiency by enhancing performance metrics recognized in earlier conversations (ford fiesta engine). Numerous methods exist to tweak an engine, each adding to enhanced fuel economy and lowered discharges

One effective strategy is changing the air-fuel ratio, guaranteeing the engine runs within the optimal combustion program. A leaner mix can enhance fuel performance, yet it has to be stabilized to stop misfires or engine knock. Furthermore, reprogramming the engine monitoring system this hyperlink can alter parameters such as ignition timing, which better improves efficiency while keeping power result.

One more important approach entails modifying the consumption and exhaust systems. Upgrading to high-performance air filters and exhaust headers can reduce back pressure, facilitating much better air flow. This enables the engine to breathe even more easily, leading to boosted combustion efficiency.

In addition, the execution of advanced adjusting tools, like dyno screening, provides accurate information that allows targeted adjustments. Regularly keeping track of these performance metrics makes certain that adjusting initiatives yield the preferred efficiency outcomes. Jointly, these strategies not just strengthen engine efficiency but additionally contribute to long-lasting sustainability in engine procedures.

Upkeep for Optimum Performance

Routine engine upkeep is vital for attaining optimal performance and durability. A properly maintained engine not only operates effectively but likewise decreases the danger of expensive repairs and break downs. Secret parts requiring routine focus include oil, filters, belts, and ignition system.

Changing the engine oil at advised periods is critical, as oil lubricates relocating components and protects against getting too hot. In a similar way, replacing oil and air filters Recommended Reading guarantees that pollutants do not harm engine feature. Neglecting these elements can cause lowered efficiency and potential engine damage.

Additionally, checking and changing used belts and tubes is essential to prevent sudden failures. Timing belts, in particular, need to be changed according to the maker's routine to avoid tragic engine damage.

Flicker plugs need to likewise be checked and changed as necessary, since they play a crucial role in ignition and gas effectiveness.

Future Patterns in Engine Technology

Accepting innovations in technology, the future of engine design is positioned to reinvent performance and performance throughout numerous applications. Hybrid and totally electric powertrains are coming to be progressively mainstream, using decreased exhausts and enhanced gas efficiency.

Furthermore, innovations in materials science are leading to lighter, stronger parts that boost engine performance while decreasing energy usage. Advanced production strategies, such as 3D printing, enable the creation of intricate geometries that improve air flow and thermal monitoring, thus maximizing burning procedures.

Additionally, the combination of expert system and maker understanding is established to transform engine diagnostics and efficiency tuning. These innovations can analyze substantial quantities of information in real time, allowing anticipating maintenance and tailored performance improvements.

Final Thought

Finally, unlocking the power of engines needs a comprehensive understanding of their auto mechanics and efficiency metrics. Applying efficient adjusting strategies and sticking to regular maintenance practices considerably improve engine capabilities. As the automobile landscape develops, accepting future trends in technology, including electrification and progressed production, will certainly be vital for optimizing efficiency and efficiency. This comprehensive method not just benefits fanatics but also adds to sustainable options in the world of automobile engineering.

Additionally, the engine counts on a very carefully calibrated fuel-air combination, ignition system, and cooling down system to ensure optimal efficiency and effectiveness.

Recognizing engine basics likewise entails recognizing the importance of engine cycles, such as the four-stroke cycle, which consists of consumption, exhaust, compression, and power strokes. Mastery have a peek at this site of these essential technicians lays the groundwork for checking out much more complicated engine characteristics and performance metrics, essential for maximizing both power result and performance.

Welcoming innovations in modern technology, the future of engine layout is positioned to transform performance and effectiveness across various applications.

Report this page